5 Current Construction Industry Challenges and How Technology Can Help

Table of Contents

Toggle [ad_1]

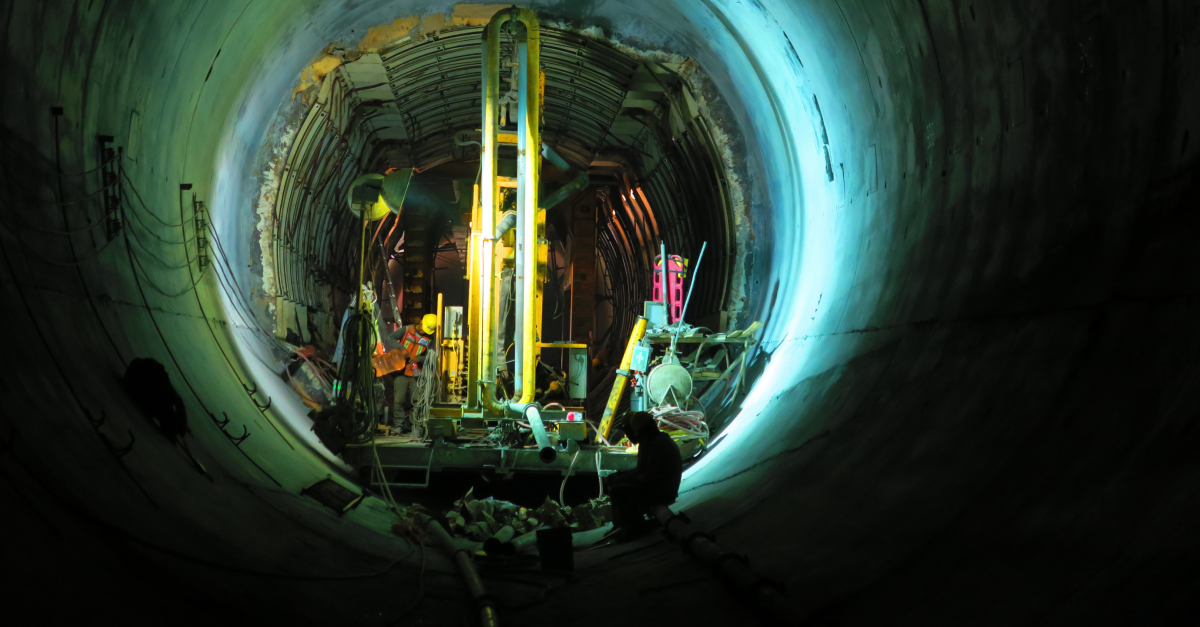

Construction hasn’t always been the most technologically advanced industry, but recent years have shown that technology has been beneficial in nearly every aspect of it. From safety training and accident prevention to AR building assistance, technology does indeed belong on the drafting table and the construction site alike.

1. Supply Chain Issues

With the current supply shortage driving up the costs of construction material, waste is not only inefficient but can also dissolve the profit of a job quickly. The fact is, without material, a job site is at a standstill. There is no substitution for timely materials and equipment.

Construction time and material costs are the majority expense of every project. When a job isn’t properly planned, you can expect the profit to be non-existent. Even worse, when mistakes are made, eating up materials and labor hours that cannot be expended, the outcome can be detrimental to the company.

Technology is assisting construction sites with materials and procurement through payment. With procurement technology advancing every day, the new cloud-based, analytic-driven, mobile procurement options ensure that materials are purchased and in place to complete the project without downtime.

2. Time Cuts Becoming a Positive Term in Construction

When planning a project, there can be hundreds of trips to the site, meetings, and plan revisions. All of these cost time and money, and in construction, those are precious commodities. What if automated measurements could be taken on-site, instead of three or four different measurements resulting in bad information?

What if construction managers were able to view prospective project adjustments by simply overlapping them with the current structure? Or if accidents on the job site were a thing of the past? How much more productive could your project manager and crew become?

Fieldwire’s platform offers an array of options that make the above pain points a breeze. Being available both offline and online, there are no more trips to the trailer or the office in the middle of your work day. On top of availability, the platform also features unlimited data storage, making file uploads hassle-free.

Augmented reality (AR), is a virtual overlay of data that adds to a person’s vision of the actual world. Construction experts may look at a worksite with additional details put immediately on top of the image by utilizing a smartphone or tablet with AR capability. AR technology assists construction workers as well: they can view prospective project adjustments before adopting them by overlaying potential project alterations right onto the job site.

Field management software solutions can streamline the process even further: overlaying newer drawing versions on top of old ones provides real-time insight into changes. Fieldwire’s platform saves all versions by default, making it easier to compare and/or use all versions at any time down the road. Adding files such as photos or specifications is another benefit that compliments the overlay options and further streamlines the workflow.

Taking advantage of plan viewing and comparison tools, task management and forms, the use of Fieldwire’s software has led to time savings of about 1 hour per worker per day – averaging in 20 hours per month for foremen and supers. The creative use of modern technology, along with all its integrations and cross-functions, inevitably leads to tangible benefits for business.

3. The Environmental Impact Needs to Be Addressed

Construction waste, fuel, emissions, and travel requirements have all led to a less than favorable view of construction when it comes to the green crowd. The heavy machinery running for weeks on end, dumpsters full of scrap building material, and the evidence of building material waste left on the site will make just about any environmentalist cringe.

Machine learning is the ability of a computer to learn a job without being programmed to perform a particular task. Machine learning is used to optimize production operations, which reduces waste and improves efficiency over time. It is also referred to as smart automation, most commonly used to lend a familiar label to smart home technology.

One major area where machine learning is expected to change construction in a major way is project management. With the algorithms picking up on material cost and availability patterns helping to better plan jobs, machine learning is expected to help prevent potential budget problems and ensure that jobs aren’t left in limbo awaiting materials. From machine scheduling to design improvement, machine learning is the future of construction.

4. Safety Incidents and Recordables

20% of worker deaths in the US are in construction, although construction employees make up only 6% of the workforce. 1 in 5 worker deaths is in the construction industry. Injury and illnesses are 24% higher among construction employees than in any other industry in the US. The best action is to plan ahead to ensure your employee’s safety and health. One accident or fatality could cost you everything if OSHA finds fault with the job site.

Technology is lending a hand to the construction industry when it comes to site safety. It’s making big leaps forward to improve workplace safety by collecting data, being able to quickly adjust to the surrounding conditions, and warning of potential hazards. With construction continuing to be afflicted with workplace accidents and deaths, wearable technology is one of the fastest-growing facets of construction technology.

Wearable smart PPE is highly responsive to both the body of the worker and to the surrounding environment. Using non-intrusive methods to do its job – via nanotechnology enhanced with an array of sensing and communication options – it delivers data to the worker and/or supervisor.

Smart hard hats and smart boots monitor the site worker and the area around them to prevent accidents and collisions with machinery. There are smartwatches that monitor workers’ health to prevent overheating and hundreds of other wearable safety items on the market. The top picks in wearable technologies in construction safety are smart helmets, smart glasses, bionic suits, smart work boots, smart safety vests, and wearable belt sensors to report slips, trips, and falls.

5. Tracking Equipment and Material on and Off-Site

Although exact figures are hard to nail down, construction equipment and material theft from job sites is estimated to be between 300 million and 1 billion annually. That number isn’t inclusive of tools that are stolen from job sites, either, so in reality, the number is much higher.

Drones already have made a significant impact in the construction industry, and their impact is expected to rise in the next year. Process expenses can be cut by using small, camera-mounted flying drones. On a large project site, purchased or leased equipment might easily go misplaced, but drones can maintain track of all equipment and materials automatically.

If nobody is working, job sites are prone to theft of supplies and equipment, but drones can watch a site especially when nobody is around. Drones have ramifications for progress reporting, employee safety, and building inspections, among other things. Increased usage of automation and artificial intelligence is one way which drones — and other forms of construction equipment and technology — will continue to get better.

To learn more about how Fieldwire can help with communication and collaboration on the jobsite, register for a live demo below.

Bryan Christiansen is the founder and CEO of Limble CMMS. Limble is a modern, easy-to-use mobile CMMS software that takes the stress and chaos out of maintenance by helping managers organize, automate, and streamline their maintenance operations.

[ad_2]

Source link